Chock Master Epoxy Resin Grouting agent(kk-100)

Chock Master Epoxy Resin Grouting agent(kk-100) Introduction: Chock Master(kk-100) is a compound consists of three-component: A) high effective epoxy resin which is non-toxic and high strength; B) hardener of low heat reaction; C) low ash and high strength aggregate. After normal mixing procedure Chock Master can effectively combine the machine itself, cement foundation and self structure in a short time. It is a grouting material with high strength, non-shrinking and flow rate. It can be adapt to machinery base, acid and alkali area and any other area that needs reducing vibration and impact.

Product characteristics: Using in a broad range of industrials: Iron and steel industry, petrochemical and oil refining industry, gas manufacture and transmission system and paper plant. Shorten the shutdown period: Quick maintenance and can reach highest physical property at 18-36HRS Fine physical characteristics: High pressure resistance, wear resistance, high tensile force resistance, deformation resistance and non-shrinking rate. Excellent chemical characteristics: The operation of the construction is easy with no other substance adding, long time of primary reaction, low heat reaction, long working time, ending reaction fast shorten maintenance period and better adhere with steel and cement with no pin-hole which makes it of acid and alkali resistance.

Application field: A. Gas engine 600Hp and above B. Reciprocating machine (compressor and pump) C. Muller and ball mill D. Punch E. Fan It can be used in those machines of high vibration value and even can be used in cement foundation mending and areas needing work restart in a short time. (Please contact the manufacturer for detailed usage in order to confirm its usage effect).

Product instruction: Chock Master(kk-100) is a stable product. After mixture, it can effectively flow to the area between machine base and cement foundation. Its fine flow rate and combination characteristic enable the machine to transform its vibration nature to cement base, dispersing its vibration and therefore allows the vibration value of the machine itself going down and enlarge the machine’s life and operation precision. Chock Master(kk-100) is a product of high physical characteristics. After hardening, its non-shrinking nature along with its high tensile force resistance, wear resistance, deformation resistance and high pressure resistance makes a close adherence to the machine, so that after a long time of operation machine still can keep its stability and precision. Chock Master(kk-100) is a product of quick and easy construction. The packing of this product is fixed shape and quantity, so during the construction period there’s no need to add other substance and can assure the product’s quality after construction finishes, thus reduces personal problem. Chock Master(kk-100) is a product of low heat reaction. Its reaction rate is low during the primary construction period, so it can effectively enlarge the working time when applied to large equipment grouting. But its ending reaction rate is high, it can effectively shorten the maintenance period and satisfy the customer. Each grouting thickness requires 50mm and when the grouting thickness is lower than this, with the consideration of its flow nature it is suggested to reduce the aggregate (C) (1/2-1 bag). Its low heat reaction nature enable the single grouting thickness to reach 6 inches (150mm) when applied to large equipment. Chock Master(kk-100) is a product of fine quality. It has many years of experience in industrial market, so it has perfect after-sale service team. In order to meet the needs of the customers please contact service staff in each region for the related information and service of the product.

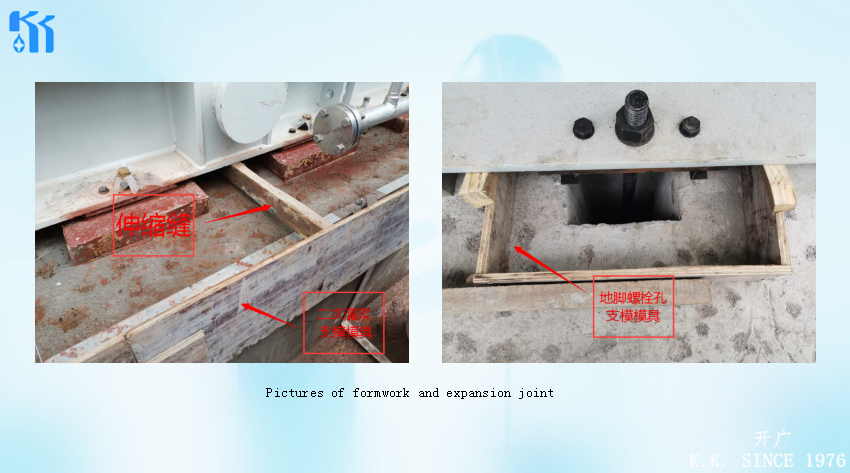

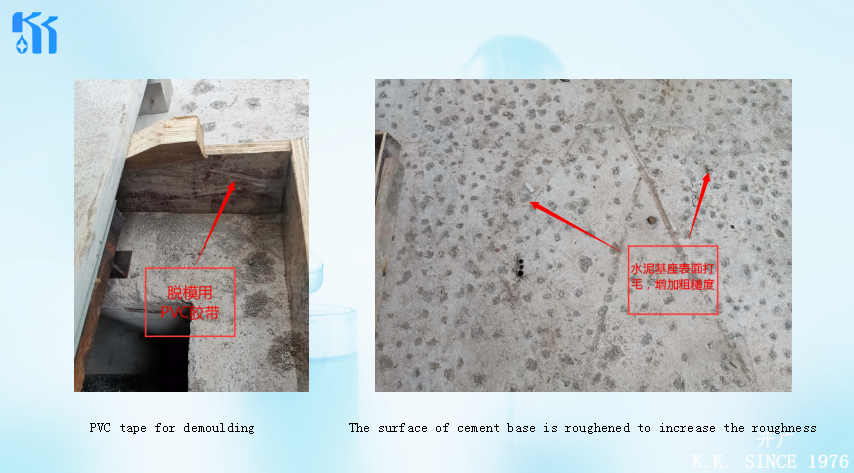

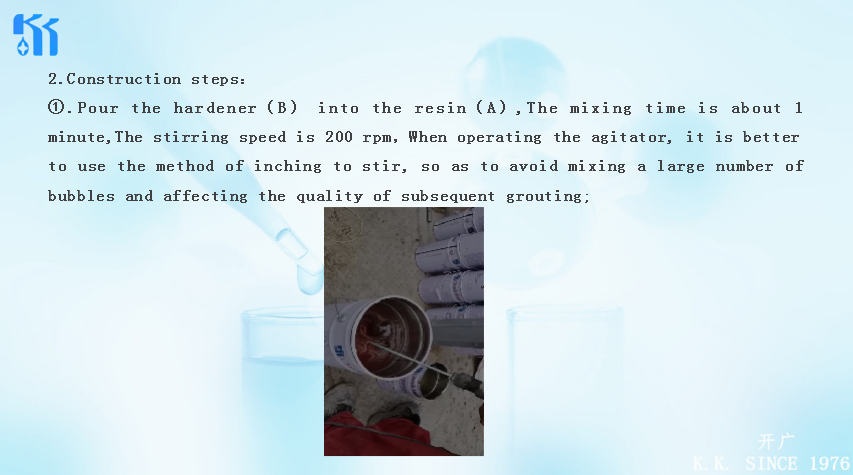

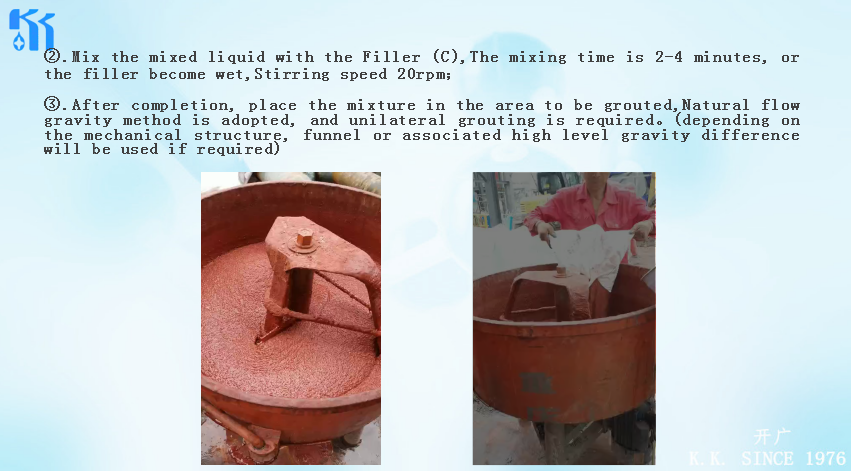

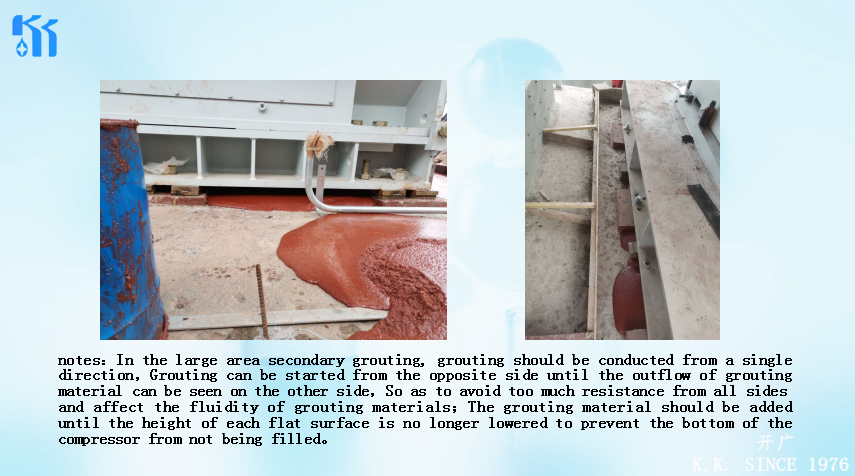

Construction instruction: Storage: 24 months storage under dry and room temperature. Preparation before construction: Temperature:18-35℃ is the suitable temperature for construction. During the construction when the atmosphere temperature is too high the ventilation system should be applied to and the construction should avoid being carried in the areas of direct sunlight (can use sunshade tools).When the temperature is too low for construction it will need cold-proof preparation. Before construction please make sure that the material temperature, atmosphere temperature and construction surface should reach this lowest temperature. Construction tools: 1.200RPM blender (mix two liquids A and B), require muddler. 2.20-40RPM mixer(mix liquid and aggregate). The motor should reach 1HP and its capacity should reach above 100 liter. 3.Cloth, water drums and water (for cleaning). 4.Release agent, wax is the best choice or PVC adhesive tape. Please don’t use liquid oil. 5.Smooth and leveling board used in making wood mould. 6.Silcon or alumina cement used in cooperating with wood mould to avoid grouting material leakage. Cement foundation: After complete maintenance of newly built cement foundation, construction can be carried out. The old existed foundation needs complete and non broken piece. The surface of the cement foundation needs roughening and the depth of roughening should remove the ash on the surface and reach gravel 50% as possible. After roughening completed, the surface of the grouting needs cleaning until no water, oil or ash can be found. Machinery preparation : The base of grouting needs cleaning with no water, oil or ash, and remove the rust as possible. When comes to hard and sharp area or area of no contact with Fillerflow please use PVC adhesive tape to wrap it. Construction procedures: 1.Put hardener (B) into resin(A) for 3 minutes’mixing at the speed of 200rpm. 2.Put mixed liquid with aggregate(C) for 2-4 minutes’ mixing or observe the accomplished wetness of the aggregate at the speed of 20rpm. 3.After completion, put the mixer into the needed grouting area and adopt natural flow gravity method. The grouting should carried out in the single side(determined by the machine structure). Filler or some related water level high gravity difference assistant should be applied for construction, if necessary. Completion of construction: 1.Check-up: can use hammer to knock the base plate. 2.Cleaning: use wet cloth to clean the machine within an hour. 3.Magma admission: use trowel to get a little solvent to make surface flat after two hours of grouting completion. 4.Removal from mould: when the environment temperature gets primary solidification after construction the mould can be removed. Expansion joint: Leave a 20mm depth expansion joint at 2M×2M×150mm area. Maintenance time(final solidification): 72hrs@15℃ 48hrs@20℃ 36hrs@27℃ 24hrs@35℃

FLOWABILITY TEST |